WINDING AND EDGING LINES

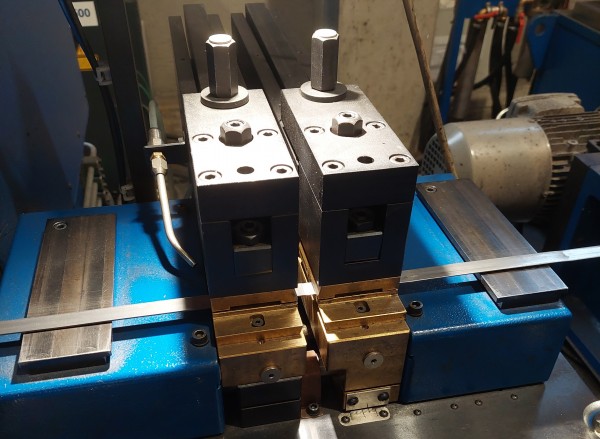

These lines differ from the traditional winding lines as they allow the edging and subsequent calibration through Skinpass of the strip to be processed. The head / tail welding can be performed using flash butt, tig or laser welding machines depending on the quality and dimensions of the strip to be welded.

Upon request, a tempering system of the welded area can be integrated for the processing of high carbon content material.

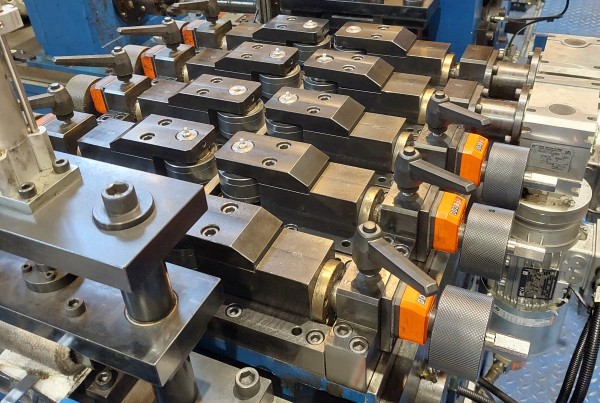

Finished reels: width up to 600 mm; internal diameter from 300 to 500 mm; external diameter up to 1.500 mm; weight up to 5.000 kg.

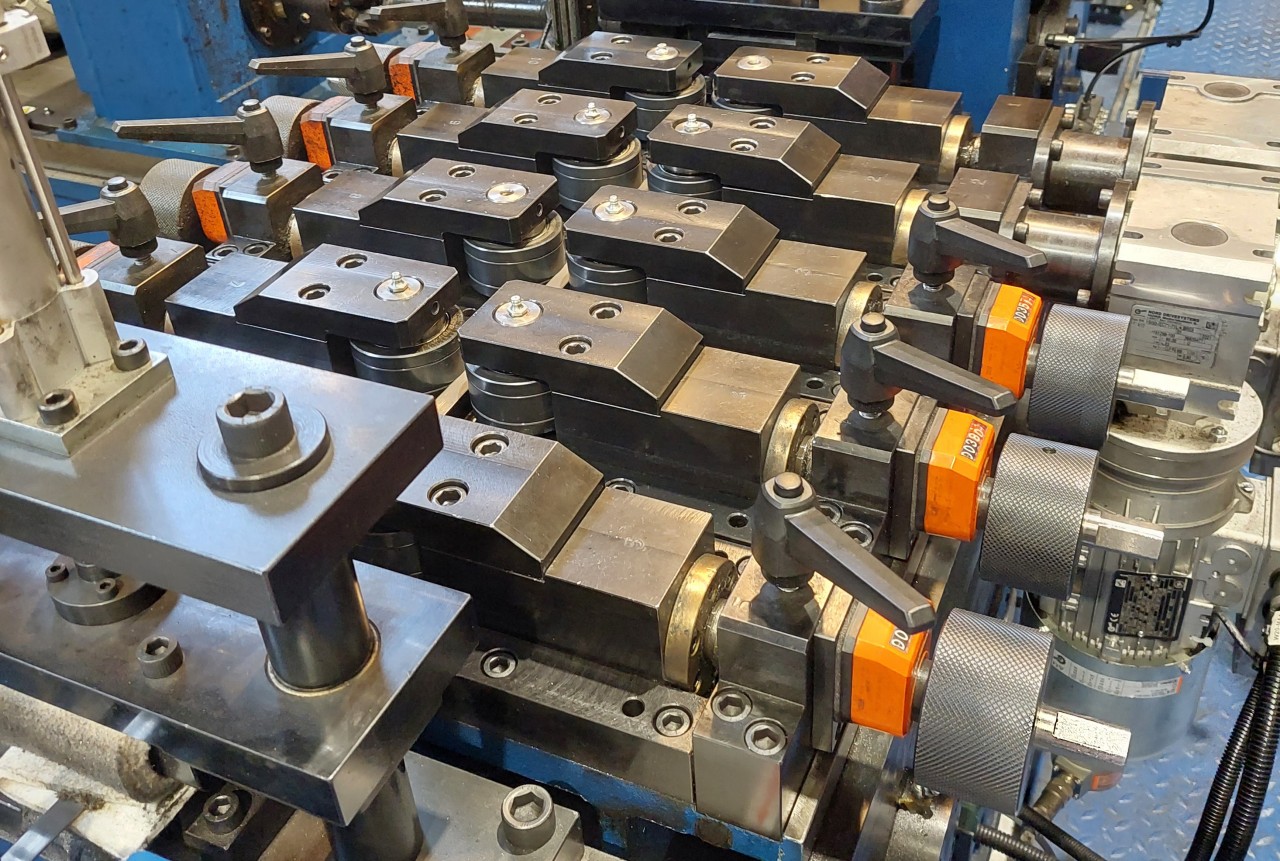

Line speed: winding from 200 to 600 m/min.

These lines differ from the traditional winding lines as they allow the edging and subsequent calibration through Skinpass of the strip to be processed. The head / tail welding can be performed using flash butt, tig or laser welding machines depending on the quality and dimensions of the strip to be welded.

These lines differ from the traditional winding lines as they allow the edging and subsequent calibration through Skinpass of the strip to be processed. The head / tail welding can be performed using flash butt, tig or laser welding machines depending on the quality and dimensions of the strip to be welded.Upon request, a tempering system of the welded area can be integrated for the processing of high carbon content material.

Finished reels: width up to 600 mm; internal diameter from 300 to 500 mm; external diameter up to 1.500 mm; weight up to 5.000 kg.

Line speed: winding from 200 to 600 m/min.