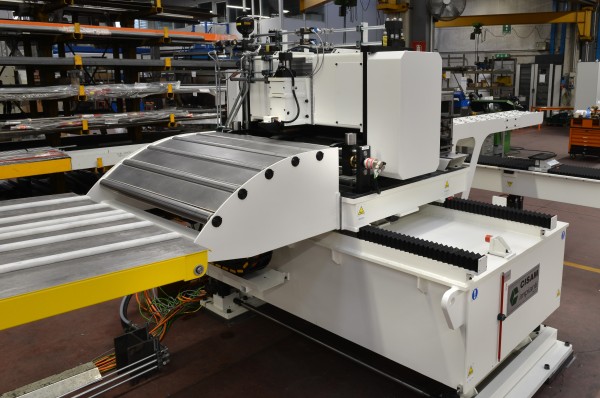

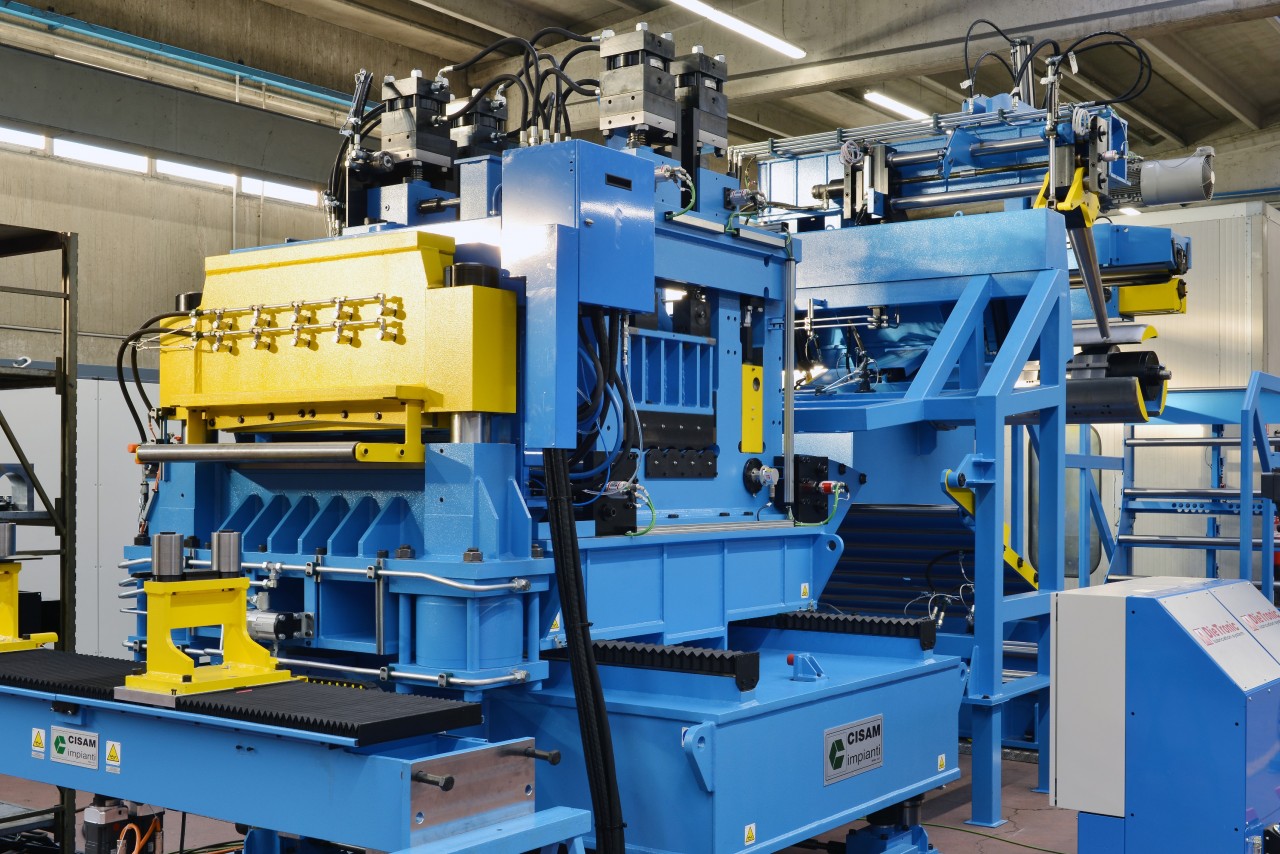

LINES WITH ZIG-ZAG SYSTEM

The lines equipped with a zig-zag feeding system allow to maximize the use of material for discs or similar production shapes. By setting the data of the disc diameter to be produced, the width and the thickness of the strip on the control panel, it is possible to obtain a reduction in the waste of material from 7%, with two figures zig-zag, up to 15% with more figures. Depending on the required characteristics (coil weight, material width and thickness, production rate, etc.) it is possible to have zig-zag lines both in long version with loop and in compact version.

The lines equipped with a zig-zag feeding system allow to maximize the use of material for discs or similar production shapes. By setting the data of the disc diameter to be produced, the width and the thickness of the strip on the control panel, it is possible to obtain a reduction in the waste of material from 7%, with two figures zig-zag, up to 15% with more figures. Depending on the required characteristics (coil weight, material width and thickness, production rate, etc.) it is possible to have zig-zag lines both in long version with loop and in compact version.